Deposition and materials processing equipment

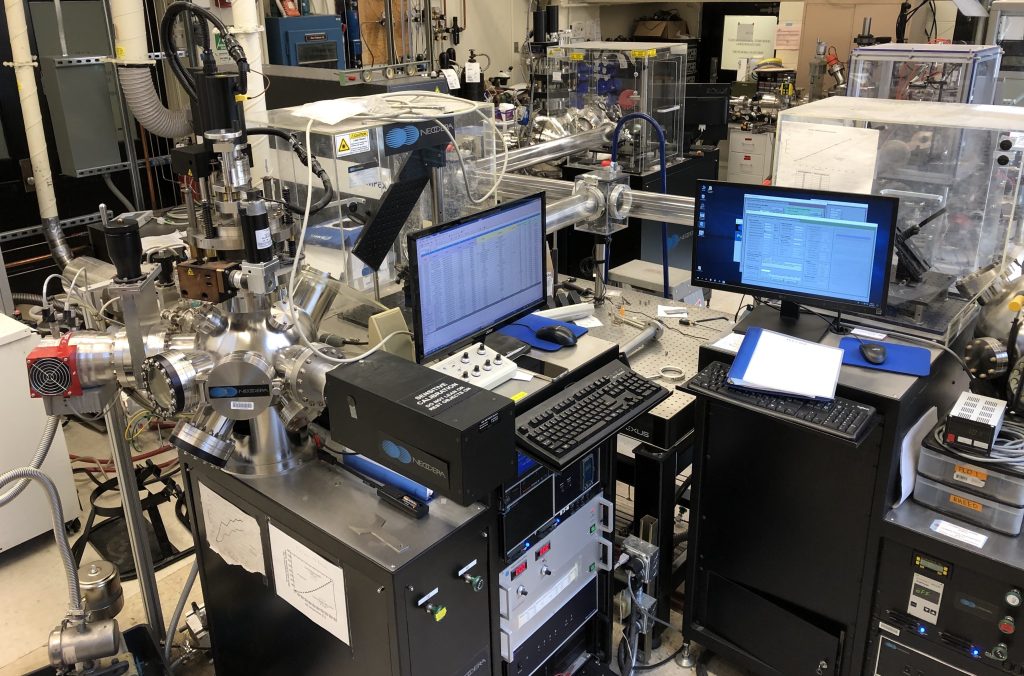

1. Pulsed Laser Deposition System

The Thin Film Laboratory includes a Neocera pulsed laser deposition system and rapid thermal annealing. The PLD system consists of a 248 nm Compex Pro excimer laser, optical table and four chambers. Each chamber has 4 or 6 target positions and capability for combinatorial deposition, with substrate temperatures up to about 900˚C in vacuum or oxygen. PLD1 has 6 targets, PLD2 has a RHEED system and is used for Bi-containing compounds, PLD3 has a confocal sputter gun, and PLD4 is used for Li-containing compounds.

2. R.F. magnetron sputter system

A loadlocked sputter system with three 5 cm diameter RF/DC sources and substrate heating.

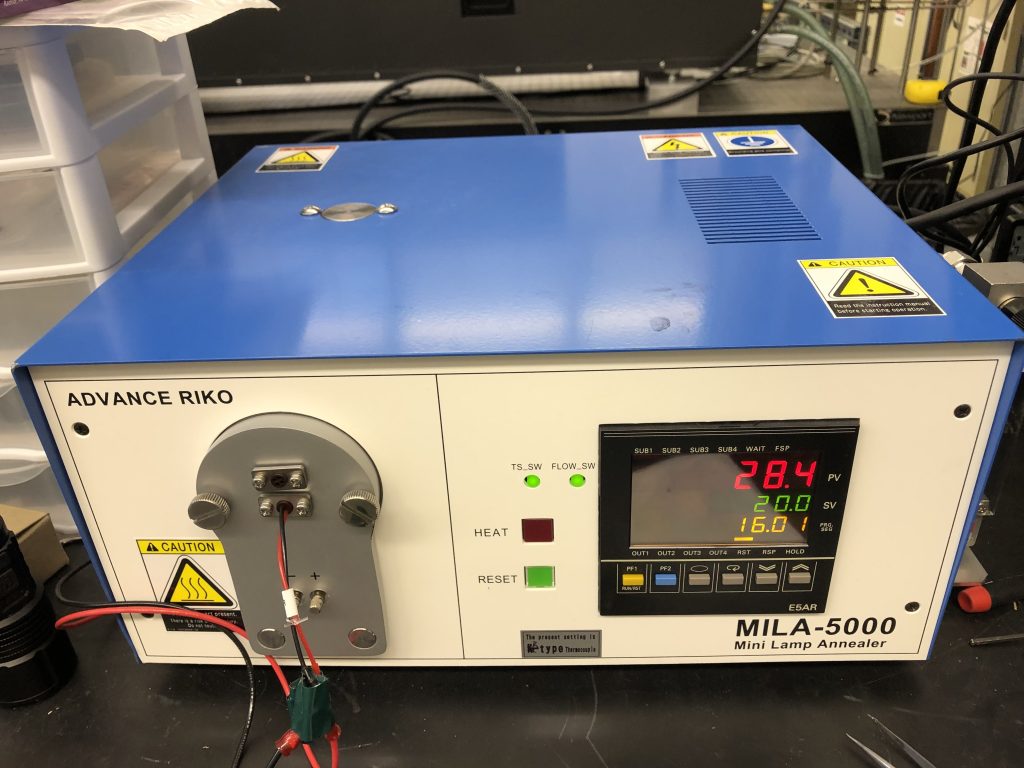

3. Rapid thermal annealing

Riko MILA 5000 heats small samples to 1000˚C in oxygen or vacuum.

4. Reactive ion etching

Plasmatherm 790 system with O2, CF4 and SF6 gases.

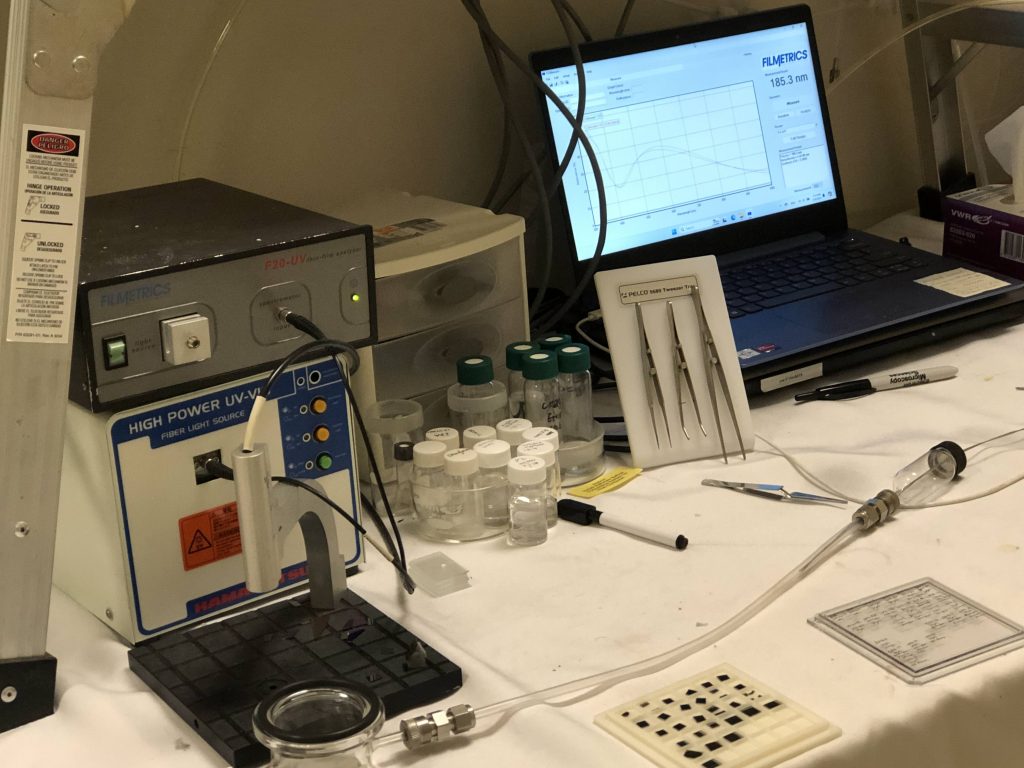

5. Block copolymer spin coating, solvent annealing, and thermal annealing

Includes Filmetrics spectral reflectometry for in situ film thickness measurement during solvent annealing.

Materials characterization equipment

1. Vibrating sample magnetometer

ADE model 1660; 1 T field with vector measureent capability and temperature control (77- 900 K).

2. Torque magnetometer

ADE model, 1 T field.

3. Magnetoresistance system

Lakeshore VSM and MR system with a heated stage.

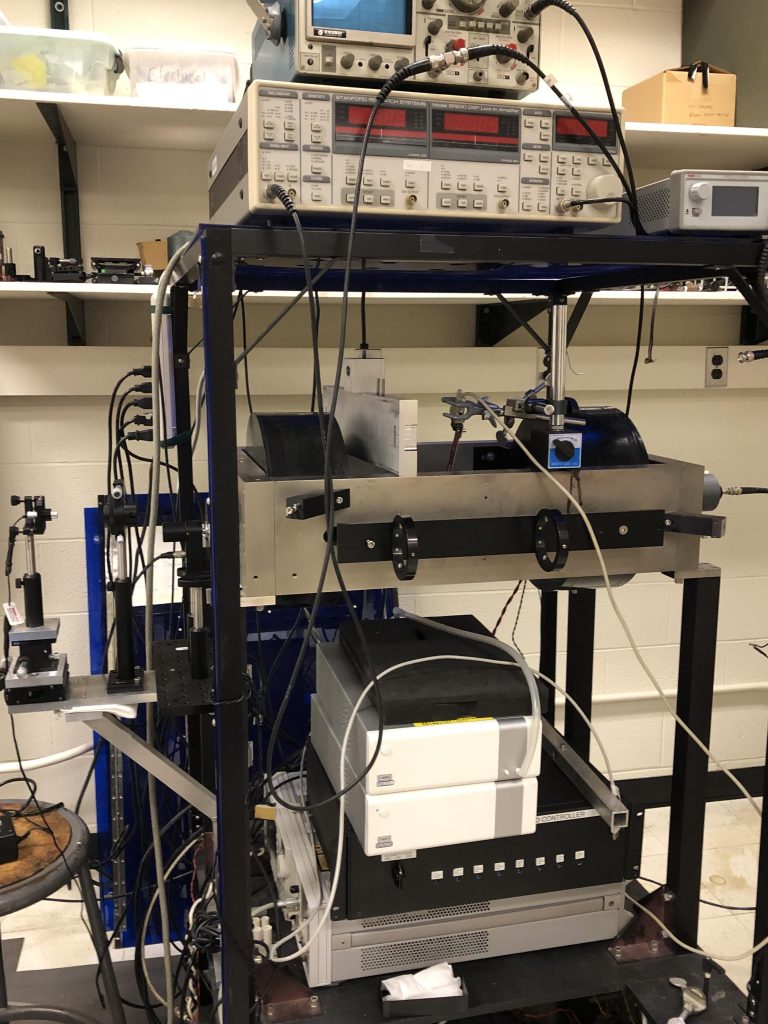

4. Faraday rotation system

Thin film samples measured in transmission with field up to 1 T, at 1550 nm or visible wavelengths.

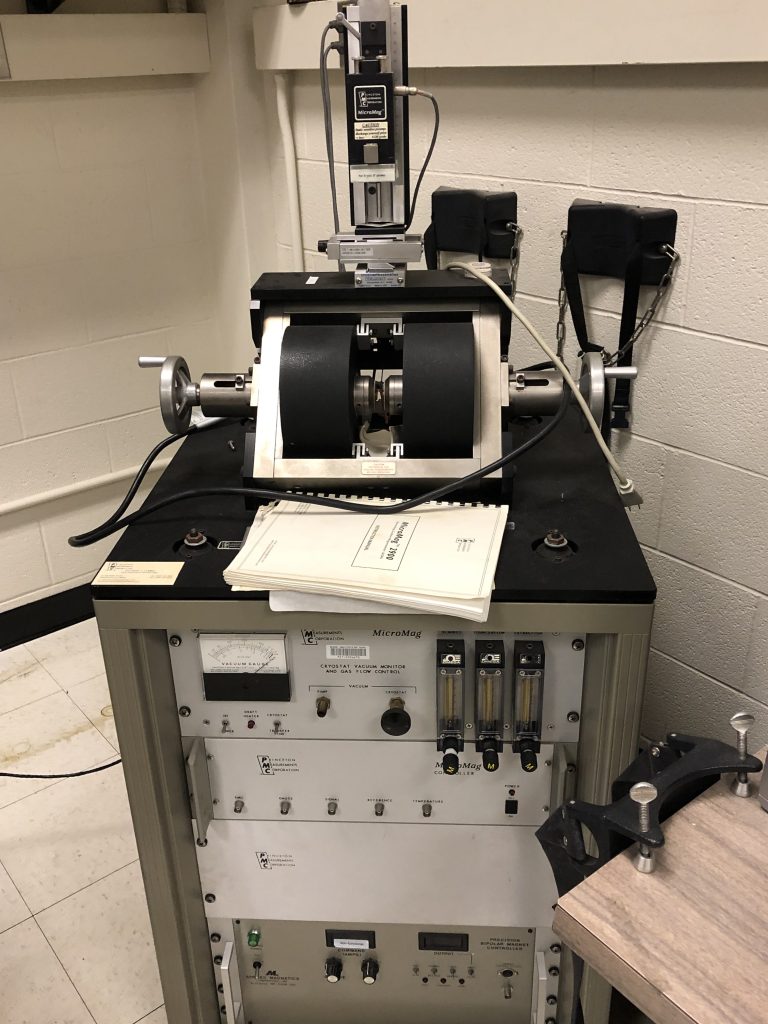

5. Alternating gradient magnetometer

Princeton Research Micromag 2900 for rapid measurements of magnetic hysteresis loops.

6. Optical microscope

7. Ferroelectric tester

Radiant Technologies Precision Premier II 200 for measuring polarization-electric field loops of ferroelectric samples.